In today’s dynamic electronics market, selecting the right touch screen technology can make or break your product's success. What is the difference between a capacitive and resistive touch screen? This is a critical question whether you're integrating a sleek 7 inch capacitive touch screen into a smart terminal or developing a rugged resistive touch screen display for industrial control. Understanding this fundamental difference is the first step toward a successful design.

At Xingyue Technology, we specialize in custom touch screen solutions. Our expertise covers both technologies, from initial design to full display integration, ensuring your product meets the stringent standards of the industrial, medical, and automotive sectors. Let our experts help you choose the perfect touch technology for your project.

What Is a Capacitive Touch Screen? A Deep Dive into Modern Touch Technology

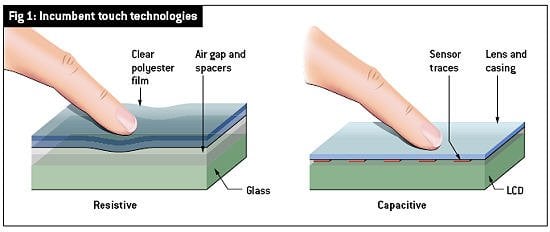

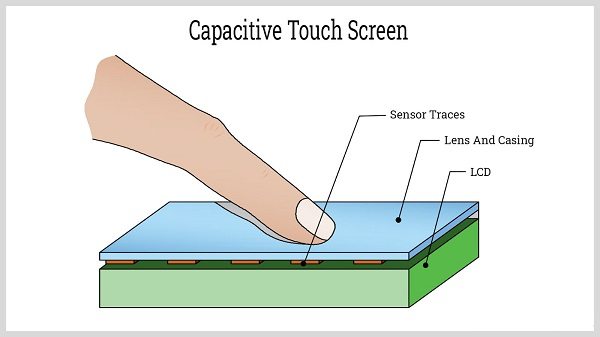

A capacitive touch screen operates by detecting the electrical properties of the human body (or a specialized stylus). When your finger touches the screen, it disrupts the display's electrostatic field, which is registered as a touch command. This technology is the standard for modern consumer electronics like smartphones and tablets.

The most common type today is the projected capacitive touch screen (PCAP), which offers superior accuracy and supports multi-touch functionality. This projected capacitive touch technology allows for intuitive gestures like pinching and swiping.

Key Features and Advantages:

Superior Image Clarity: With no air gap in many designs, the TFT LCD capacitive touchscreen offers vibrant colors and high transparency.

Multi-Touch Support: The capacitive multi-touch screen is ideal for complex applications requiring gesture control.

High Durability: The top layer is often made of scratch-resistant glass, making it incredibly durable for public-facing or high-use devices.

Sensitive and Responsive: It requires only a light touch to activate, providing a smooth and effortless user experience.

Common Applications for Capacitive Displays:

Medical Devices: High-resolution screens for diagnostic equipment and patient monitoring.

Smart POS & Payment Terminals: Providing a seamless checkout experience for retail.

Automotive Control Panels: Modern in-car displays with a premium look and feel.

Industrial HMIs: Ruggedized industrial capacitive touch screen panels for smart factory control.

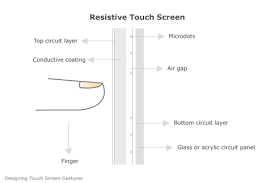

What Is a Resistive Touch Screen? The Workhorse of Industrial Applications

A resistive touch screen consists of two flexible layers coated with a conductive material, separated by a thin air gap. When a user applies pressure to the top layer, it touches the bottom layer, completing a circuit and registering the touch location.

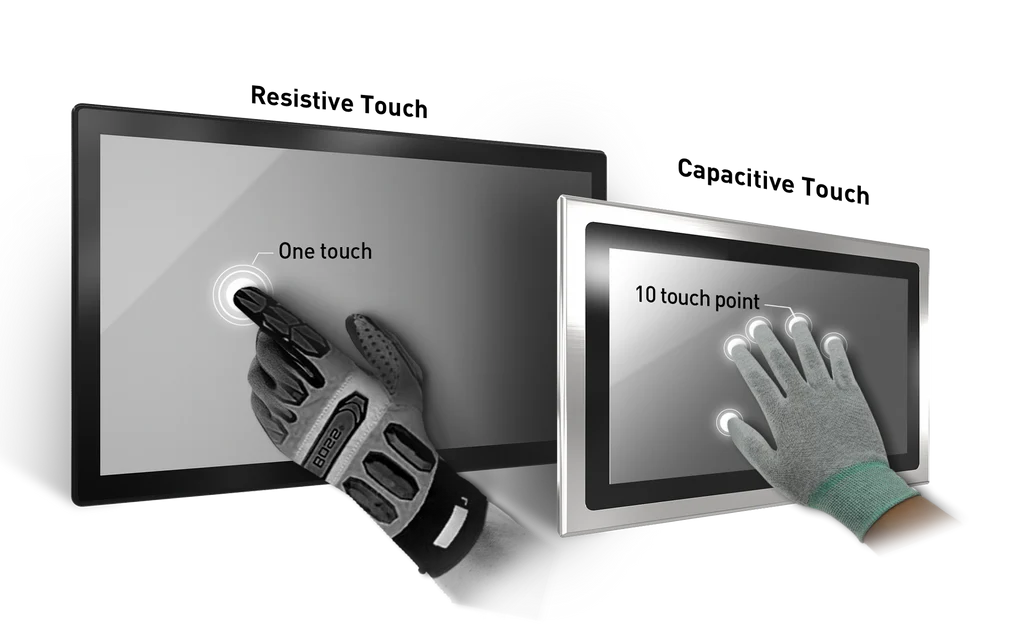

This pressure-based mechanism is what makes resistive technology incredibly versatile. It doesn't rely on electrical conductivity, meaning it can be activated by a gloved finger, a stylus, a pen, or any solid object.

Key Features and Advantages:

Pressure-Activated: Works with any input method, including gloves and styluses, which is essential in many industrial and medical settings.

High Resistance to Contaminants: Less susceptible to false touches from dust, oil, or water droplets.

Lower Power Consumption: Generally more power-efficient, making it suitable for battery-powered or portable devices.

Cost-Effective: Often a more budget-friendly option, especially for simpler applications.

Common Applications for Resistive Panels:

Outdoor Equipment: Where users may be wearing gloves or the screen is exposed to the elements.

Factory Machinery: Control panels in manufacturing environments where durability is paramount.

Transportation Control Systems: Reliable interfaces for logistics and public transport.

Medical Monitoring Equipment: Where doctors and nurses often wear gloves.

Capacitive vs. Resistive: A Head-to-Head Comparison

To help you decide, here’s a quick comparison of the two technologies:

| Feature | Capacitive Touch Screen | Resistive Touch Screen |

|---|---|---|

| Activation Method | Light touch (electrical conductivity) | Pressure (physical contact) |

| Multi-Touch | Yes, excellent for gestures | Typically single-touch |

| Clarity & Brightness | Excellent (up to 90% light transmission) | Good (75-85% light transmission) |

| Durability | High (scratch-resistant glass surface) | Good (durable but flexible top layer can be damaged by sharp objects) |

| Input Flexibility | Finger or special stylus | Finger, gloved hand, stylus, any object |

| Cost | Generally higher | More cost-effective |

| Ideal For | Consumer electronics, modern HMIs, medical imaging | Industrial controls, POS, rugged devices |

Complete Customization Expertise at Xingyue Technology

We understand that one-size-fits-all doesn’t apply in real-world applications. Our engineering team helps you choose the right technology and then customizes every aspect to fit your needs perfectly. Whether you need a custom capacitive touch panel or a custom resistive touch screen, we have the solution.

Our Customization Options Include:

Touch Screen Size: From a compact 2.8 inch TFT to a large 32 inch full panel.

Interface: LVDS, RGB, MIPI, HDMI, USB, and more.

Touch Type: We offer 4-wire and 5-wire resistive touch screens or advanced projected capacitive multi-touch solutions.

Display Modules: Choose from TFT LCDs, high-contrast IPS LCDs, vibrant OLEDs, or simple HDMI-based screens.

Glass & Bonding: We provide custom cover glass with options for anti-glare (AG), anti-reflective (AR), and anti-fingerprint (AF) coatings, plus optical bonding for supreme durability and sunlight readability.

Overlays: We can design a capacitive touch screen overlay or a resistive touch screen overlay to upgrade existing non-touch displays.

We also support hobbyist and prototyping projects, including DIY capacitive touch screens, Arduino resistive touch screen shields, ESP32 capacitive touch projects, and various displays for Raspberry Pi.

Why Choose Xingyue Technology as Your Manufacturing Partner?

Choosing a supplier is as important as choosing a technology. Here’s why global clients trust us:

✅ Certified Quality: We are ISO 9001:2015 & IATF 16949 Certified, ensuring our processes meet the highest international standards.

✅ Deep Experience: With over 15 years in touch module manufacturing, we’ve seen it all and can guide you past common pitfalls.

✅ Complete In-House Engineering: We manage everything from FPC and LCD design to cover glass and final bonding, ensuring seamless integration and quality control.

✅ Flexible Partnership: We support both OEM/ODM models, from full custom capacitive touch panel design to simple branding on a proven platform.

✅ Agile & Accessible: We offer low MOQs for custom projects and provide fast prototyping to accelerate your development cycle.

Whether you're developing a self capacitance touch screen for a medical device or a 4-wire resistive touch industrial monitor, Xingyue is your trusted partner from concept to completion.