In-vehicle display Automotive & Motorcycle Displays

>Automotive Grade Vibration Resistant Touch Displays

Designed for demanding vehicle and outdoor applications, our vibration-resistant automotive displays comply with IEC 60068-2-64 and MIL-STD-810G standards for shock and vibration endurance. Featuring reinforced mechanical structures, optical bonding for improved durability, and wide-temperature operation, they deliver consistent touch accuracy and visual clarity even in heavy-duty trucks, agricultural machinery, marine vessels, and construction equipment. Custom sizes, interfaces, and protective glass options are available for OEM/ODM projects.

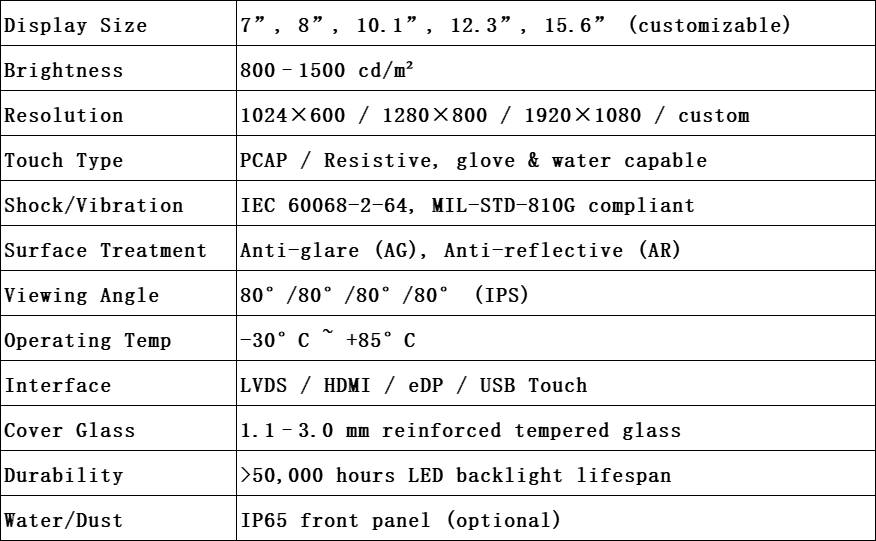

Display Size 7”, 8”, 10.1”, 12.3”, 15.6” (customizable)

Brightness 800–1500 cd/m²

Resolution 1024×600 / 1280×800 / 1920×1080 / custom

Touch Type PCAP / Resistive, glove & water capable

Shock/Vibration IEC 60068-2-64, MIL-STD-810G compliant

Surface Treatment Anti-glare (AG), Anti-reflective (AR)

Viewing Angle 80°/80°/80°/80° (IPS)

Operating Temp -30°C ~ +85°C

Interface LVDS / HDMI / eDP / USB Touch

Cover Glass 1.1–3.0 mm reinforced tempered glass

Durability >50,000 hours LED backlight lifespan

Water/Dust IP65 front panel (optional)

Our vibration-resistant automotive touch displays are built to withstand continuous shocks and vibrations, ensuring stable performance in harsh vehicle environments. Designed for trucks, buses, off-road, marine, and industrial vehicles.

Heavy-duty trucks & buses

Off-road construction machinery

Agricultural vehicles & equipment

Marine control panels & navigation

Military & defense vehicles

Railway and metro driver consoles

OEM/ODM mechanical design for vibration endurance

Reinforced glass and housing options

Interface, brightness, and touch customization

Optical bonding for enhanced shock resistance

Certified Durability – Meets international shock/vibration standards.

Long-Term Reliability – Consistent performance in demanding conditions.

Full Customization – Tailored for specific vehicle models and environments.

Global Manufacturing – ISO/TS 16949 automotive-grade production.

They comply with IEC 60068-2-64 and MIL-STD-810G for shock and vibration endurance.

Yes, from -30°C to +85°C for reliable outdoor and vehicle use.

Yes, we provide OEM/ODM design for size, interface, glass thickness, and mechanical structure

Absolutely. Their vibration resistance, IP65 protection, and high brightness make them ideal for marine, rail, and off-road uses.

Copyright © 2025 Hunan Xingyue Technology Co., Ltd All rights reserved