The term TFT display is the foundation of modern screen technology, but the landscape is evolving. Engineers and product designers now face critical choices: What is a TFT display used for? How does it compare in a TFT VS IPS VS OLED matchup? And how can you source a custom TFT display module for a specific application like an industrial HMI? This comprehensive guide will answer these questions, breaking down how a TFT display works and exploring its crucial role in today's electronic devices.

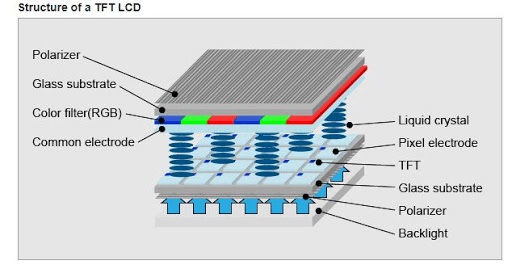

Core Principle: How a TFT Display Works

At its heart, a TFT (Thin-Film Transistor) display is an active-matrix LCD (Liquid Crystal Display). Unlike older passive-matrix screens that were slow and imprecise, a TFT display assigns a microscopic transistor and capacitor to each individual pixel.

This structure provides several key advantages:

- Precise Control: Each pixel is controlled directly, preventing electrical "crosstalk" from neighboring pixels.

- High Image Quality: This precise control allows for sharp, stable images with high resolution and contrast.

- Fast Response Times: The active matrix enables high refresh rates, essential for smooth video and responsive interfaces.

The thin-film transistor acts as a tiny switch for each pixel, making the vibrant, high-resolution screens we use every day possible.

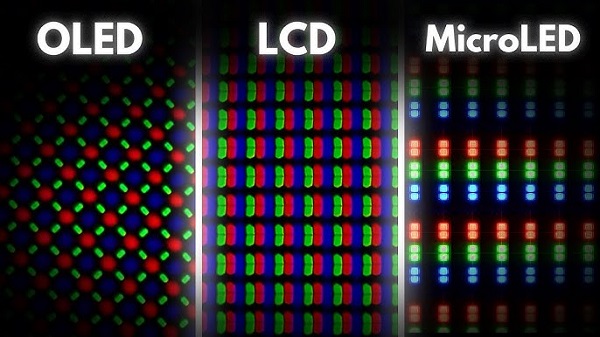

The Great Debate: TFT VS IPS VS OLED

Choosing the right display technology is a critical decision. Let's compare the three main contenders in today's market.

| Feature | Standard TFT (TN Panel) | IPS (In-Plane Switching) Display | OLED (Organic Light Emitting Diode) Display |

|---|---|---|---|

| How it Works | Liquid crystals twist perpendicularly. | Liquid crystals rotate parallel (in-plane). | Each pixel is an organic compound that emits its own light. |

| Viewing Angles | Limited; color shifts when viewed off-center. | Excellent (178°/178°). Colors remain consistent. | Excellent. Perfect colors from any angle. |

| Color Reproduction | Good; sufficient for many applications. | Superior. High color accuracy and richness. | Best. Widest color gamut and true blacks. |

| Contrast Ratio | Good. | Very Good. | Infinite. Pixels can turn completely off, creating true black. |

| Response Time | Fast. | Good, but can be slightly slower than TN. | Instantaneous. Near-zero pixel response time. |

| Power Consumption | Moderate; backlight is always on. | Slightly higher than TN due to backlight structure. | More efficient, especially with dark content, as pixels are off. |

| Best For | Cost-sensitive projects, high-refresh-rate gaming. | Applications requiring color accuracy and wide viewing angles. | Premium devices demanding the best possible image quality. |

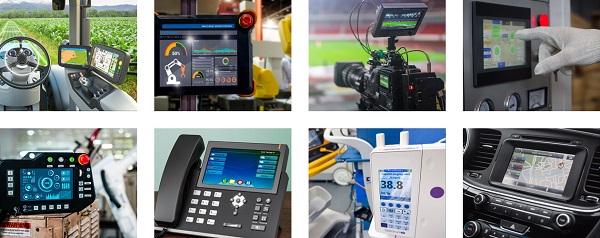

Common Applications: What is a TFT Display Used For?

The versatility and cost-effectiveness of TFT technology make it the workhorse across countless industries. Its applications are vast and varied.

TFT LCD for Industrial HMI

In factory settings, a TFT LCD for industrial HMI (Human-Machine Interface) is the standard. These displays must be rugged, reliable, and viewable under various lighting conditions. Often paired with a resistive touch panel, they allow operators wearing gloves to control machinery with precision.

Medical and Scientific Instruments

Medical devices, from patient monitors to diagnostic equipment, rely on high-resolution TFT screens. IPS display variants are often preferred here for their superior color accuracy and wide viewing angles, ensuring that multiple healthcare professionals can view critical data clearly from different positions.

Automotive and Transportation

Modern vehicle dashboards and infotainment systems are built around automotive-grade TFT displays. They are engineered to withstand extreme temperatures and vibration while providing bright, clear information to the driver.

Consumer and Smart Home Devices

From thermostats to coffee makers, a simple TFT screen provides a modern, intuitive user interface that is far superior to traditional button-based controls.

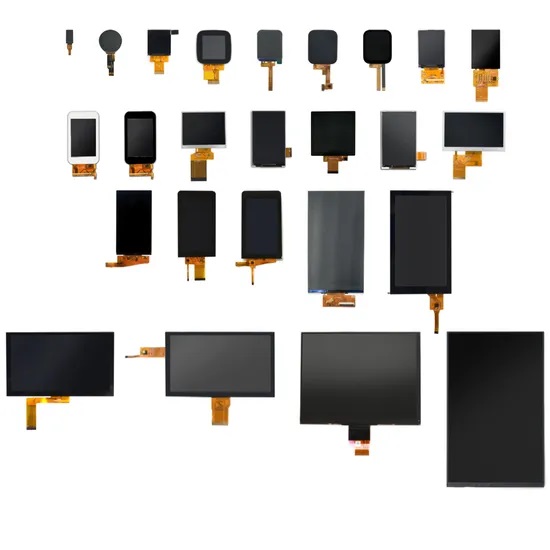

Beyond Off-the-Shelf: The Custom TFT Display Module

For many specialized applications, a standard display is not enough. This is where a custom TFT display module becomes essential. Customization allows you to create a display that perfectly fits your product's unique mechanical and electronic requirements.

Customization options can include:

- Custom Dimensions and Shapes: Creating displays with unique sizes, aspect ratios, or even non-rectangular shapes.

- Enhanced Brightness: Modifying the backlight for sunlight readability in outdoor applications.

- Custom FPC (Flexible Printed Circuit): Designing the connector cable to fit your specific board layout.

- Integration of a Touch Screen: Creating a seamless touch screen with TFT display assembly.

Working with a manufacturer that specializes in custom solutions allows you to build a truly optimized and differentiated product.

Choosing the Right TFT Solution

Understanding how a TFT display works is the first step. The next is choosing the right variant—be it a cost-effective TN, a color-accurate IPS, or a premium OLED—for your needs. Furthermore, for unique applications ranging from an industrial HMI to a specialized medical device, partnering with a manufacturer for a custom TFT display module can provide a significant competitive advantage. The right display technology is not just a component; it's a cornerstone of your product's success.

Frequently Asked Questions (FAQ)

1. Can a TFT screen also be a touch screen? Yes, absolutely. A TFT display is the visual component. A separate touch-sensitive layer (either capacitive or resistive) is typically laminated on top of it to create an integrated touch screen with TFT display.

2. Is an IPS display a type of TFT? Correct. IPS (In-Plane Switching) is an advanced type of TFT LCD technology. While "TFT" refers to the fundamental active-matrix transistor structure, "IPS" refers to the specific alignment of the liquid crystals, which provides superior color and viewing angles compared to older TN-type TFT panels.

3. What should I consider when sourcing a custom TFT display module? When sourcing a custom TFT display module, key considerations include the manufacturer's engineering capabilities, their experience with your specific industry (e.g., medical, automotive), their quality control processes, and their ability to manage the supply chain for all custom components. To get started on your custom project, you can submit your specifications to our engineering team here.