Looking for a durable, high-performance multi-touch solution for your next project? Whether it's for industrial HMI, medical displays, or commercial kiosks, Projected Capacitive (PCAP) technology delivers both precision and ruggedness. As a leading capacitive touch technology supplier, we often find that engineers and product managers need a deep understanding of how this technology works to make the best design choices. This technical guide will deconstruct the core principles of the PCAP touch screen, exploring its fundamental components and the science that enables true multi-touch functionality.

What is a PCAP Touch Screen? Moving Beyond Surface Capacitive

To understand PCAP, it is helpful to differentiate it from its predecessor, surface capacitive technology. This distinction highlights the key innovation that made modern touch interfaces possible.

A Quick Recap of Surface Capacitive Limitations

Surface capacitive technology uses a single conductive layer on the glass surface with sensors at the corners. While functional for single-touch applications, it suffered from lower accuracy and was susceptible to surface damage and environmental interference.

The "Projected" Field: The Key Innovation

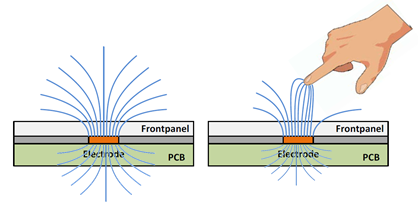

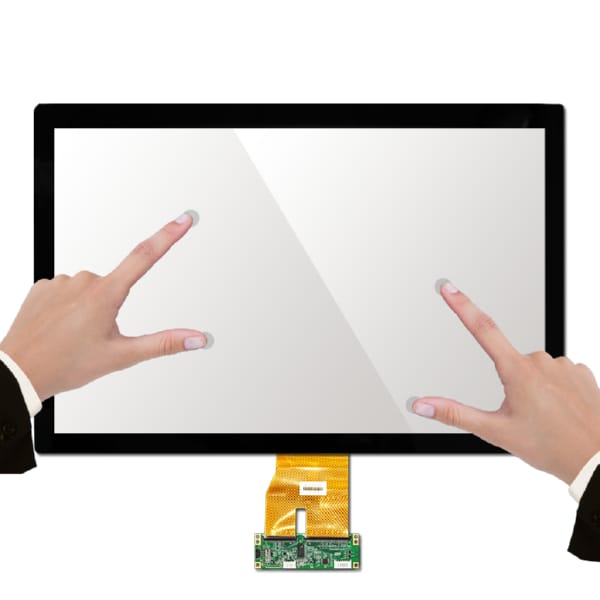

The term "projected" is key. In a PCAP touch screen, the sensing electrodes are placed behind the protective top layer of glass. They project an electrostatic field through the glass to the surface. This design not only protects the sensitive components but also enables a host of advanced features.

The Core Component: The X-Y Electrode Grid

The heart of any PCAP device is a meticulously designed grid of electrodes. This grid forms an invisible matrix that acts as the sensing area for the entire screen.

Materials Used: Indium Tin Oxide (ITO)

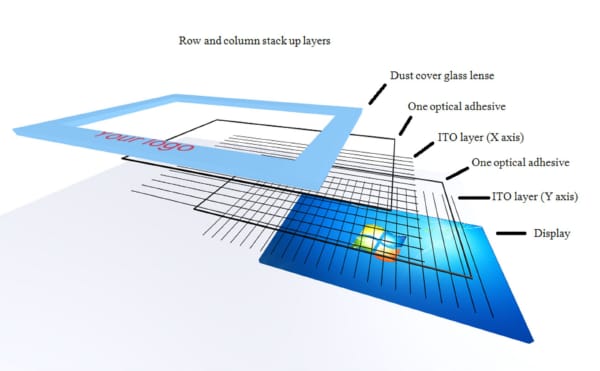

This grid is typically made from Indium Tin Oxide (ITO), a transparent conductive material. The ITO grid is etched onto a substrate, like film or glass, allowing it to be integrated into the display stack-up without obstructing the view of the screen.

Common Grid Patterns (e.g., Diamond, Matrix)

Engineers design the electrode grid in various patterns, such as diamond or matrix layouts, to optimize for sensitivity and linearity. The choice of pattern depends on the screen size, required resolution, and specific application needs.

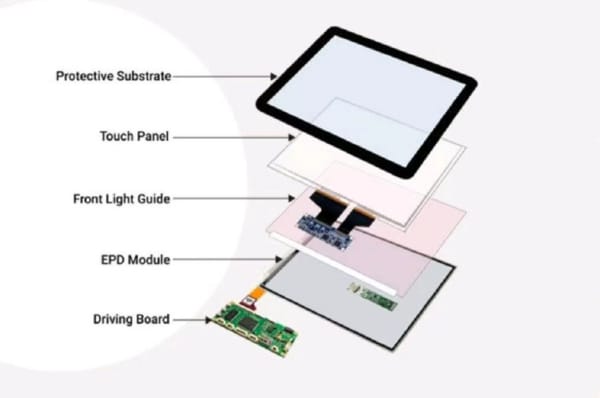

How the Grid is Integrated into the Screen Stack-up

The ITO grid can be placed on a separate sensor layer or directly onto the display's cover glass or the LCD cell itself (on-cell/in-cell). This integration method affects the final thickness and optical performance of the display.

The Two Methods of Sensing: Mutual Capacitance vs. Self-Capacitance

A PCAP controller can detect a touch using one of two fundamental methods. The choice between them determines the screen's ability to handle multi-touch input.

Mutual Capacitance: Measuring the Charge Between Electrodes

In a mutual capacitance system, the X and Y electrodes are arranged in a matrix of intersecting lines. The controller measures the capacitance at each intersection point. When a finger approaches an intersection, it draws away some of the electrical charge, causing a measurable drop in capacitance at that specific X-Y coordinate.

Self-Capacitance: Measuring the Charge of a Single Electrode to Ground

In a self-capacitance system, the controller measures the capacitance of each individual X and Y electrode relative to a system ground. When a finger touches the screen, it increases the capacitance of the corresponding X and Y electrodes. The controller then identifies the intersection of the activated electrodes.

A Comparison Table: Accuracy, Speed, and Multi-Touch Capability

| Feature | Mutual Capacitance | Self-Capacitance |

|---|---|---|

| Multi-Touch | Yes. Can detect and track multiple, independent touch points simultaneously. | No. Prone to "ghosting" or ambiguity with more than two touches. |

| Accuracy | Very high; detects precise coordinate points. | Good, but can be less precise at the intersection. |

| Speed | Generally faster scanning for large screens. | Can be faster for smaller screens with fewer electrodes. |

| Common Use | The standard for nearly all modern multi-touch devices. | Used in some single-touch applications or for specific features like wake-on-touch. |

How Mutual Capacitance Enables True Multi-Touch

The superiority of mutual capacitance is its ability to deliver a true multi-touch experience. This capability is fundamental to modern gesture control.

Scanning the Matrix: How the Controller Detects Multiple Points

Because the controller measures the capacitance at every unique intersection in the grid, it can construct a complete "image" of all touch points on the screen's surface. It can independently identify and track the coordinates of 10, 20, or even more simultaneous touches.

Differentiating Between Real Touches and "Ghosting"

Self-capacitance systems can suffer from "ghosting." For example, if you touch at (X1, Y1) and (X2, Y2), the system also sees false activations at (X1, Y2) and (X2, Y1). Mutual capacitance eliminates this ambiguity by pinpointing the exact intersection, making it far more reliable.

The Foundation of Modern Gesture Control

The ability to track multiple points accurately is what allows for intuitive gesture control like pinch-to-zoom, rotation, and complex multi-finger swipes. This is all made possible by the underlying capacitive touch technology based on mutual capacitance.

Advantages of Projected Capacitive Touch Technology in Modern Devices

The widespread adoption of projected capacitive touch technology is driven by a clear set of benefits that align with the demands of modern product design.

- Unmatched Accuracy and Responsiveness: PCAP offers extremely high precision and a light, responsive touch feel.

- Superior Durability and Vandal Resistance: With the sensors protected behind glass, the surface is highly resistant to scratches, abrasion, and contaminants, increasing product durability.

- Support for Sleek, Bezel-Free Designs: The technology allows for edge-to-edge glass designs, creating modern, aesthetically pleasing, and easy-to-clean bezel-free products.

- Through-Glass and Gloved-Hand Operation Capabilities: Advanced PCAP controllers and tuning can enable through-glass touch (e.g., through a shop window) and operation with certain types of gloves.

Customizing PCAP Technology with Xingyue

Understanding the theory is one thing; implementing it is another. As an experienced multi-touch display module manufacturer, we specialize in tailoring PCAP technology to meet specific environmental and operational needs. At Xingyue Technology, we offer customizable PCAP touch modules from 3.5" to 65" with various options, including ITO glass or film sensors, and advanced controller tuning for glove and water usage. This expertise is crucial for creating a successful PCAP touch screen for industrial applications or medical devices.

PCAP: The Unseen Force Behind Today's Intuitive Interfaces

In conclusion, projected capacitive touch technology is the sophisticated engine driving the intuitive interfaces we use every day. Its X-Y electrode grid, combined with the precision of mutual capacitance sensing, provides the robust foundation for the accurate, durable, and multi-touch experiences that users now expect. As leading touch screen manufacturers, we leverage our deep understanding of this technology to build the next generation of interactive devices.

Frequently Asked Questions (FAQ)

1. Does PCAP technology work with gloves? Standard PCAP screens require a conductive touch (like a finger). However, with specialized controllers and advanced signal tuning, it is possible to create a PCAP touch screen that works with certain types of thin medical or industrial gloves.

2. What is the maximum number of touch points a PCAP screen can support? The maximum number of touch points is determined by the touch controller IC and its firmware. Most modern controllers easily support 10 simultaneous touch points, while more advanced systems can track 20, 40, or more, making them suitable for large, collaborative interactive displays.

3. How does water or moisture affect a PCAP touch screen? Because water is conductive, it can disrupt the screen's electrostatic field, potentially causing false or inaccurate touches. However, advanced controllers employ sophisticated algorithms for water rejection and wet-finger tracking, allowing for reliable operation even in moist conditions.

Need a customized PCAP solution for your device? Whether you require a standard size or a completely unique design, our team is ready to assist. Contact us today for samples, datasheets, or a free technical consultation with our engineers.

Click Here to Start Your Custom PCAP Project