A touch display for medical devices is far more than a standard screen. It is a critical human-machine interface where accuracy, reliability, and safety are non-negotiable. From patient monitors in an ICU to surgical consoles in an operating room, these displays must perform flawlessly under demanding conditions while adhering to stringent regulatory standards. This guide provides an in-depth look at the essential engineering features that define a high-performance Medical Equipment Display, focusing on the core pillars of infection control, visual clarity, operational reliability, and long-term durability.

Essential Feature #1: Infection Control with Anti-Bacterial Coatings

In any clinical setting, high-touch surfaces are a primary vector for pathogen transmission. The screen of a medical device is one of the most frequently touched surfaces, making infection control a paramount concern.

How Nano-Silver and Other Anti-Bacterial Coatings Work

Modern Anti-Bacterial Coatings are a critical first line of defense. These coatings, often utilizing materials like nano-silver ions or specialized chemical compounds, are integrated into the glass surface. They work by disrupting the cellular metabolism of bacteria and other microbes, inhibiting their growth and preventing the formation of harmful biofilms.

The Importance of Surface Hygiene in High-Touch Areas

The integration of an antimicrobial surface does not replace regular cleaning, but it provides continuous, active protection between sanitation cycles. This is crucial for enhancing patient and practitioner safety in environments like hospital wards, clinics, and diagnostic labs.

Long-Term Efficacy and Durability

A key engineering challenge is ensuring these coatings maintain their efficacy over the device's lifespan, even after repeated cleaning with harsh chemicals. A true medical touch screen features a coating that is bonded at a molecular level to resist degradation.

Essential Feature #2: Uncompromised Clarity with High Brightness Displays

Visual accuracy is critical for clinical decision-making. A medical display must present information clearly and consistently, regardless of ambient lighting conditions.

Why Operating Rooms Demand High Brightness (800+ Nits)

The intense overhead lighting in operating rooms and surgical suites can easily wash out a standard display. A High Brightness Display, typically rated at 800 nits or higher, is essential to ensure that vital signs, imaging data, and user interface elements remain perfectly legible.

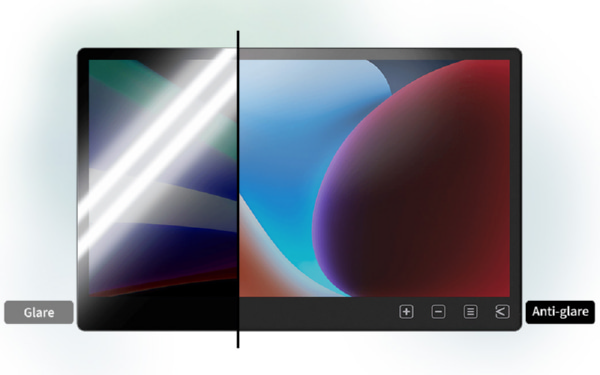

The Role of Optical Bonding in Reducing Glare

Beyond brightness, controlling glare is crucial. Optical bonding—the process of laminating the cover glass directly to the LCD—eliminates internal reflections. This dramatically improves the screen's contrast ratio and clarity, making the image appear sharper and easier to read, even under challenging lighting.

Maintaining Image Consistency Across Viewing Angles (IPS Technology)

Medical professionals often view screens from various angles. Using an IPS (In-Plane Switching) display panel ensures wide viewing angles with minimal color shift. This guarantees that all members of a clinical team see the same accurate information, regardless of their position relative to the Medical Equipment Display.

Essential Feature #3: Flawless Operation with Advanced Touch Control

The touch performance of a medical device must be absolutely reliable. False or missed touches can have serious consequences. This requires a touch controller and sensor tuned for the unique demands of a clinical environment.

Seamless Performance with Surgical Gloves and Wet Hands

Clinicians frequently operate devices while wearing latex or nitrile surgical gloves. A medical-grade touch display for medical devices must be calibrated for precise glove touch and even function reliably when the screen surface or the user's hands are wet.

Robust EMI Shielding for a Crowded Electronic Environment

Hospitals are filled with a vast array of electronic equipment, creating a high-EMI (Electromagnetic Interference) environment. A medical touch screen must incorporate robust EMI shielding to prevent interference that could cause erratic touch performance or "ghost" touches.

Meeting the Stringent Requirements of IEC 60601

IEC 60601 is a series of technical standards for the safety and essential performance of medical electrical equipment. A display intended for medical use must be designed and tested to meet these stringent requirements for electrical safety, emissions, and immunity.

Essential Feature #4: Durability and Resistance to Cleaning Agents

Medical devices are subjected to rigorous and frequent cleaning protocols. The materials and construction must be able to withstand this demanding regimen over many years of service.

Chemically Strengthened Cover Glass for Impact and Scratch Resistance

The display's cover glass must be highly resistant to both impacts and the fine scratches that can harbor bacteria. Chemically strengthened glass provides a durable, non-porous surface that maintains its integrity.

Designing Housings that Withstand Harsh Disinfectants

The bezel and housing of the display must be made from materials that are resistant to common hospital-grade cleaning agents and disinfectants, such as alcohol and bleach solutions, without cracking, clouding, or degrading.

Ensuring Long-Term Reliability Through Rigorous Testing

Every component of a medical display must undergo extensive durability testing. This includes chemical wipe tests, mechanical stress tests, and accelerated aging tests to ensure reliable performance throughout the product's entire lifecycle.

A Comparison: Standard vs. Medical Grade Touch Screen

The differences between a standard commercial display and a purpose-built medical grade touch screen are substantial.

| Feature | Standard Commercial Display | Medical Grade Touch Screen |

|---|---|---|

| Brightness | 250-400 nits | 800-1000+ nits |

| Surface | Standard Glass | Anti-Bacterial Coating, Chemical Resistant |

| Touch Operation | Bare finger only | Glove Touch, Wet-Hand Operation |

| EMI/Safety | Standard FCC/CE | Robust EMI Shielding, Designed for IEC 60601 |

| Durability | Basic | High Impact Resistance, Withstands Harsh Cleaning |

Engineering for Life: Partnering with an Expert in Medical Touch Displays

Selecting a touch display for medical devices is a critical engineering decision that directly impacts patient safety and clinical outcomes. It requires a deep understanding of medical standards, materials science, and advanced electronics. Partnering with a supplier that has proven expertise in this field is essential to developing a compliant, reliable, and successful medical product.

Frequently Asked Questions (FAQ)

1. What is the typical lifespan of an anti-bacterial coating? The lifespan of high-quality Anti-Bacterial Coatings is designed to match the operational life of the medical device itself. Because the antimicrobial properties are integrated into the glass material rather than being a simple surface layer, they remain effective even after years of regular and rigorous cleaning.

2. Can your displays be calibrated to the DICOM standard for medical imaging? Yes. For diagnostic imaging applications, our displays can be calibrated to meet the grayscale requirements of the DICOM (Digital Imaging and Communications in Medicine) Part 14 standard. This ensures accurate and consistent representation of medical images.

3. How does optical bonding help in a medical environment? Optical bonding provides two key benefits in a medical setting. First, it enhances clarity and reduces glare under bright operating room lights. Second, it increases the display's physical durability and impact resistance, which is crucial for mobile medical equipment. For a detailed analysis of your medical device needs, you can contact our medical solutions team today for a free consultation.