A Medical Display is one of the most critical components in modern healthcare technology. Unlike a standard commercial screen, a display integrated into a Medical Equipment Display is a precision instrument that directly impacts clinical excellence, from diagnostic accuracy to patient safety. Engineering these displays requires a deep understanding of stringent regulatory standards, unique use-case challenges, and specialized technologies. This guide provides a comprehensive overview of the key considerations in Medical Display Technology, covering everything from fundamental quality systems to specific application requirements.

The Foundation of Trust: Why ISO 13485 Certification Matters

Before discussing any technical feature, the conversation must begin with quality management. For medical device manufacturing, this is the non-negotiable foundation of trust and compliance.

What is ISO 13485? A Standard for Medical Device Quality

ISO 13485 is an internationally recognized standard that specifies the requirements for a quality management system (QMS) for the medical device industry. A supplier that is ISO 13485 certified has demonstrated that their processes for design, development, production, and service consistently meet both customer and regulatory requirements.

The Importance of a Certified Supply Chain

For a medical device OEM, partnering with an ISO 13485 certified display manufacturer is critical. It de-risks your supply chain, simplifies your own regulatory approval process, and provides documented assurance that your display partner adheres to the same high standards of quality and traceability that you do.

Application #1: Displays for Patient Monitoring Systems

In an ICU or at a patient's bedside, the display on a patient monitor is a vital information hub. Its primary job is to convey critical data clearly and reliably, 24/7.

Critical Requirements: Wide Viewing Angles and Unfailing Reliability

Patient Monitoring Systems must be viewable from multiple angles by different members of a clinical team. This makes wide viewing angles essential. Furthermore, these devices must operate without failure for years, demanding the highest level of component reliability.

The Role of IPS Technology in Patient Monitoring Systems

IPS (In-Plane Switching) technology is the standard for high-performance Patient Monitoring Systems. It provides exceptionally wide viewing angles (typically 178°/178°) with minimal color or contrast shift, ensuring all caregivers see the same accurate information.

Clear and Unambiguous Alarm Visualization

The display must be able to render alarms and warnings with absolute clarity. This involves high contrast ratios and the ability to display saturated colors so that critical alerts are instantly recognizable.

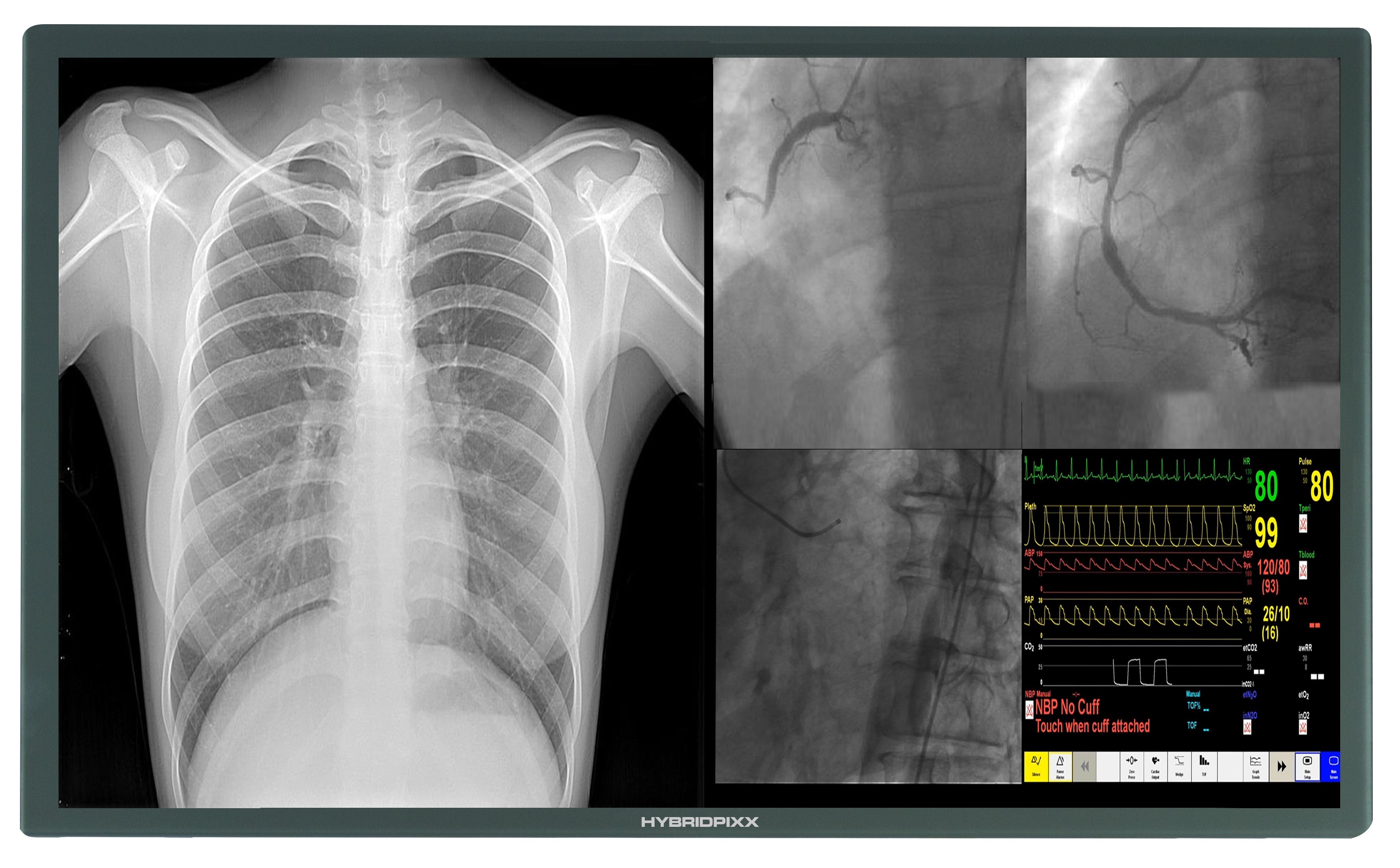

Application #2: High-Clarity Medical Imaging Displays

For diagnostic purposes, such as viewing X-rays, MRIs, or ultrasounds, the demands on a Medical Imaging Display are even more rigorous. Here, the display is a diagnostic tool.

The Demand for High Resolution and High Contrast

To reveal subtle anatomical details, these displays require high resolution (often 2MP, 4MP, or higher) and a very high contrast ratio to distinguish between slight variations in tissue density.

Understanding the DICOM Standard for Grayscale Accuracy

DICOM (Digital Imaging and Communications in Medicine) Part 14 is a standard that dictates how grayscale images should be displayed to ensure perceptual consistency. A true diagnostic display must be factory-calibrated or calibratable to the DICOM grayscale standard function.

The Importance of Color Calibration for Diagnostic Displays

For color imaging applications like endoscopy or doppler ultrasound, precise and consistent color calibration is essential for accurate diagnosis.

Application #3: Interactive Medical Terminal Displays

From electronic health record (EHR) terminals to surgical consoles, interactive displays in healthcare must combine visual performance with flawless, safe operation.

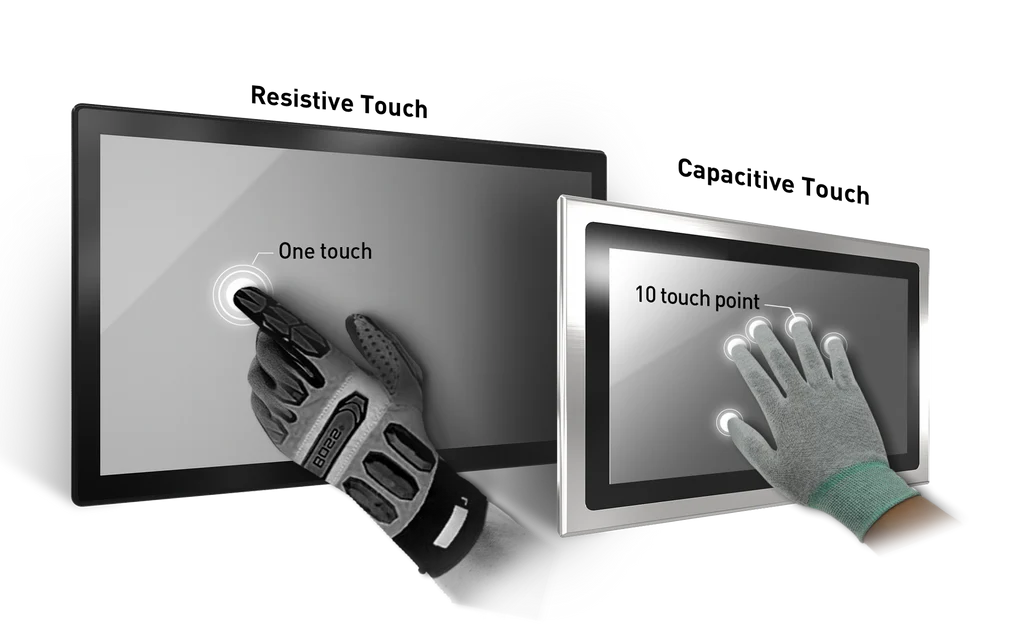

Touch Performance with Surgical Gloves

A primary requirement for any interactive Medical Display in a clinical or surgical setting is the ability to respond perfectly to a user wearing surgical gloves. The touch controller must be specifically tuned for glove touch sensitivity.

Resistance to Harsh Cleaning Agents

These devices are subjected to frequent cleaning with aggressive chemical disinfectants. The cover glass, coatings, and housing must be engineered to withstand these cleaning agents without degradation, clouding, or damage.

The Role of Anti-Bacterial Surfaces

To further enhance infection control, many modern Medical Touch Screen Solutions incorporate Anti-Bacterial surfaces. These are typically achieved with specialized coatings or glass treatments that inhibit the growth of microbes on the high-touch screen surface.

Core Technologies in Modern Medical Touch Screen Solutions

Across these applications, several core technologies are consistently required to build a compliant and high-performance medical touch screen.

- Anti-Bacterial and Easy-to-Clean Surfaces: Utilizes materials and coatings that inhibit microbial growth and can withstand frequent sanitation.

- High Brightness and Optical Bonding for OR Environments: A High Brightness panel (800+ nits) combined with optical bonding is essential to reduce glare and maintain clarity under intense operating room lights.

- IEC 60601 Compliance for Electrical Safety and EMI: The entire display assembly must be designed to meet the IEC 60601 standards for electrical safety and electromagnetic immunity (EMI) to ensure it does not interfere with or be affected by other critical medical equipment.

Choosing the Right Partner for Your Medical Display Project

Developing a Medical Equipment Display is a complex engineering challenge that requires deep domain expertise. It involves navigating a landscape of stringent regulations, demanding use cases, and specialized technologies. The right manufacturing partner is not just a component supplier; they are a collaborator who understands the intricacies of the medical device industry.

Frequently Asked Questions (FAQ)

What is the difference between a clinical review display and a diagnostic display?

A diagnostic display is a high-end monitor used by radiologists for making primary diagnoses and must strictly adhere to standards like DICOM. A clinical review display is used by physicians on the ward or in consultation rooms to view images and data; while it requires high quality, its specifications are generally less stringent than a primary diagnostic display.

How do you validate the effectiveness of an anti-bacterial coating?

The effectiveness of Anti-Bacterial coatings is validated through standardized laboratory testing, such as JIS Z 2801 or ISO 22196. These tests measure the coating's ability to inhibit the growth of common bacteria (like E. coli and Staphylococcus aureus) over a 24-hour period.

Are your Medical Touch Screen Solutions compatible with common medical-grade cleaning agents?

Yes. Our Medical Touch Screen Solutions are designed and tested for compatibility with a wide range of common hospital-grade disinfectants and cleaning agents. We provide detailed information on chemical resistance in our product datasheets. Developing a medical device that demands the highest standards? Partner with an ISO 13485 certified expert.