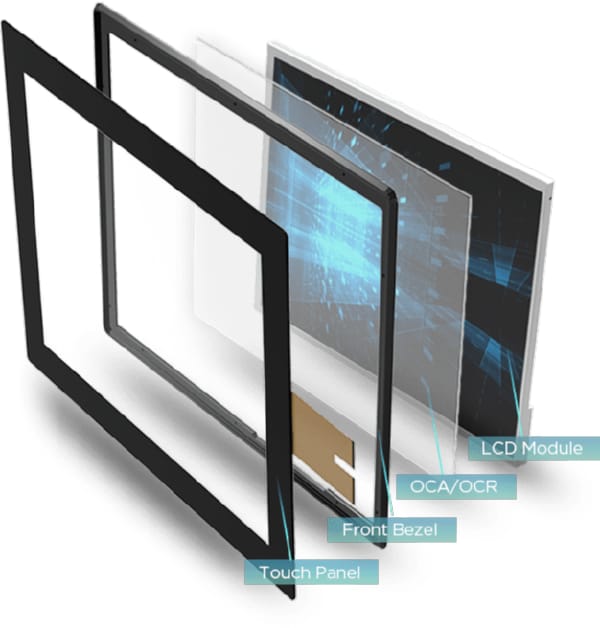

The performance of a modern capacitive touch screen depends on more than just its controller IC; its physical construction is equally critical. For engineers and product designers, understanding the different touch screen stack-up options is essential to balancing performance, thickness, and cost. This guide will decode the anatomy of the modern capacitive panel touch screen, providing a detailed explanation of the common acronyms CTP, GG, and GFF. By the end, you will have a clear framework for selecting the optimal structure for your next touch screen module.

What is a CTP (Cover Lens Touch Panel)? Defining the Term

Before comparing specific structures, it's important to define a foundational term: CTP. This acronym is frequently used in the industry, and a clear understanding prevents confusion.

The Role of the Cover Lens (or Glass Cover)

The "Cover Lens" is the topmost layer of the touch panel—the surface the user physically interacts with. It is typically made of a durable material like chemically strengthened glass. The primary function of this glass cover is to protect the underlying sensor and display while providing a smooth, high-quality user experience.

CTP as a General Term for Capacitive Sensors

CTP simply stands for "Cover Lens Touch Panel." It is a general industry term for a capacitive touch sensor assembly that is designed to be laminated with a cover lens. Therefore, both GG and GFF are types of CTP touch panel constructions.

The GG (Glass-Glass) Structure: A Deep Dive

The GG structure is renowned for its robustness and superior optical qualities. As the name implies, its core construction is based on two layers of glass.

Anatomy of a GG Touch Screen: The Stack-up

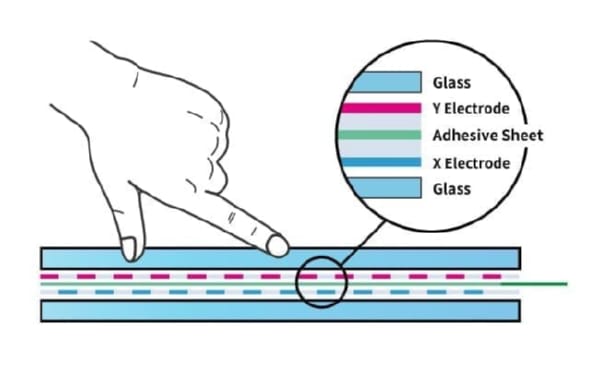

A GG touch screen consists of a top cover lens and a second piece of glass that serves as the sensor substrate. The transparent conductive ITO (Indium Tin Oxide) grid is etched directly onto this sensor glass. These two glass layers are then bonded together.

Advantages: Superior Durability and Optical Clarity

- High Durability: The rigid glass sensor substrate provides excellent structural integrity and surface hardness. This makes the GG touch screen highly resistant to scratches and impacts, a critical feature for industrial and public-use devices.

- Excellent Optical Clarity: Glass has superior light transmission properties compared to film. This results in better brightness and a higher-quality visual experience, with minimal color distortion.

Disadvantages: Thickness and Cost Considerations

- Increased Thickness and Weight: The use of a second glass layer makes the overall touch screen module thicker and heavier.

- Higher Cost: Glass is more expensive to process than film, making the GG structure a more premium and costly option.

The GFF (Glass-Film-Film) Structure: A Deep Dive

The GFF structure is a popular alternative that prioritizes a thinner profile and lower cost by replacing the glass sensor with flexible films.

Anatomy of a GFF Structure: The Stack-up

A GFF structure consists of a top cover lens, followed by two layers of optical PET (polyester) film. Each film layer has an ITO conductive circuit etched onto it, typically with one layer for the X-axis and the other for the Y-axis. These layers are laminated together with an optical adhesive.

Advantages: Thinner Profile and Cost-Effectiveness

- Thinner and Lighter: Replacing the sensor glass with ultra-thin films significantly reduces the overall thickness and weight of the touch panel. This is a crucial advantage for portable and handheld devices.

- Lower Cost: PET film and its processing are generally less expensive than glass, making the GFF structure a more budget-friendly choice.

Disadvantages: Optical Performance and Surface Hardness

- Reduced Optical Clarity: While high-grade optical films are used, their light transmittance is typically slightly lower than that of pure glass, which can result in a minor reduction in brightness and optical clarity.

- Lower Surface Hardness: The film-based sensor is not as scratch-resistant as a glass sensor, though this is less of a concern as it sits protected behind the durable top glass cover.

GG vs. GFF Structure: A Head-to-Head Comparison

To simplify the selection process, this table provides a direct comparison of the key performance metrics for each structure.

| Feature | GG (Glass-Glass) Structure | GFF (Glass-Film-Film) Structure |

|---|---|---|

| Durability / Hardness | Excellent. High impact and scratch resistance. | Good. Durable, but less rigid than an all-glass construction. |

| Thickness / Weight | Thicker and heavier. | Thinner and lighter. Ideal for sleek designs. |

| Optical Clarity | Excellent. Highest light transmittance (~91%). | Very Good. Slightly lower transmittance (~86-89%). |

| Cost | Higher. More expensive materials and processing. | Lower. More cost-effective for mass production. |

| Flexibility | Rigid. Not suitable for curved surfaces. | Can be adapted for slightly curved surfaces. |

Which Structure is Right for Your Touch Screen Module?

The optimal choice between a GG touch screen and a GFF structure is entirely dependent on the specific requirements of your application.

When to Choose the GG Structure: Industrial and Medical Applications

For devices that operate in harsh environments or require maximum durability and the best possible optical performance, the GG structure is the superior choice. Its robustness makes it ideal for industrial control panels, medical equipment, and public-facing kiosks.

When to Choose the GFF Structure: Consumer and Portable Devices

For products where a slim profile, light weight, and cost are primary design drivers, the GFF structure is often the best fit. This includes consumer electronics like tablets, smart home devices, and other portable gadgets.

Factors to Consider in Your Design

When making your decision, evaluate these key trade-offs:

- What is the maximum allowable thickness for your touch screen module?

- What is the target price point for your bill of materials (BOM)?

- What level of impact and scratch resistance does your product's use case demand?

Making an Informed Decision for Your Next Touch Panel Design

Understanding the fundamental differences between GG and GFF constructions is the first step toward creating a successful product. By carefully analyzing the trade-offs between durability, thickness, optical clarity, and cost, you can select a capacitive panel touch screen structure that perfectly aligns with your design goals and user expectations.

Frequently Asked Questions (FAQ)

1. Are there other structures like OGS (One Glass Solution)? Yes, other structures exist, such as OGS (One Glass Solution), where the ITO sensor is integrated directly onto the cover glass. OGS offers the thinnest profile but is typically more expensive and less durable if the cover glass is damaged. GG and GFF remain the most common and balanced choices for most applications.

2. How does the choice of structure affect the overall thickness of the touch screen module? The structure is a primary determinant of the final thickness. A GFF stack-up can be significantly thinner than a GG stack-up because it replaces a rigid glass sensor (typically 0.55mm or thicker) with two optical films (each often less than 0.1mm).

3. For a custom touch screen, can we combine features of different structures? While the fundamental GG and GFF structures are distinct, a custom touch screen project allows for significant flexibility. For instance, you can specify a particularly thick and durable glass cover for a GFF module to enhance its robustness. For a detailed analysis of your options, it's best to consult with our engineering team.