Selecting the correct touch screen interface is a foundational decision in any hardware integration project. This choice dictates how the touch panel communicates with the host processor, impacting everything from hardware design and software development to system performance and cost. For engineers, understanding the trade-offs between the primary communication protocol options—I2C, USB, and RS232—is essential. This guide provides a definitive technical comparison to help you select the optimal interface for your specific application, whether it's a deeply embedded system or a rugged industrial panel.

The Role of the Touch Screen Controller and Its Interface

Before comparing the interfaces themselves, it's crucial to understand their context. The physical touch sensor generates raw analog data; it's the touch screen controller that translates this data into digital coordinates. The interface is the pathway for sending these coordinates to the main processor.

The Bridge Between Sensor and Processor

Think of the interface as the bridge. A fast, reliable bridge ensures data gets across without errors or delays. A poorly chosen bridge can become a bottleneck, no matter how good the sensor or the processor is.

Why Your Interface Choice Matters

Your choice of interface has direct consequences:

- Hardware Design: It determines the number of pins (pin count) required on your mainboard.

- Software Development: It affects the complexity of the driver development.

- Performance: It impacts data transfer speed (data rate) and reliability over distance.

- System Cost: It can influence both component and development costs.

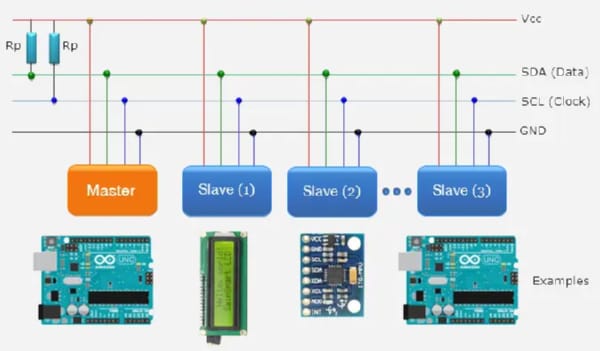

I2C (Inter-Integrated Circuit): The Embedded Standard

I2C is a ubiquitous serial communication protocol found in countless embedded systems. For connecting peripherals directly to a microcontroller (MCU), it is often the default choice.

Anatomy of the I2C Protocol: Two Wires, Multiple Devices

The primary appeal of an I2C touch screen is its simplicity. It requires only two signal lines—SDA (Serial Data) and SCL (Serial Clock)—plus power and ground. Multiple devices can share the same two-wire bus, each with a unique address.

Advantages: Low Pin Count and Simplicity for MCUs

For board-level communication, I2C is incredibly efficient. The low pin count saves precious I/O on a microcontroller, and the protocol is well-supported by virtually all MCUs, simplifying firmware development. This makes it ideal for compact, cost-sensitive devices.

Limitations: Shorter Distance and Slower Speeds

I2C is designed for short-distance, on-board communication, typically limited to less than a meter. Its data rate is also slower compared to USB, which can be a consideration for very high-resolution or high-report-rate touch panels.

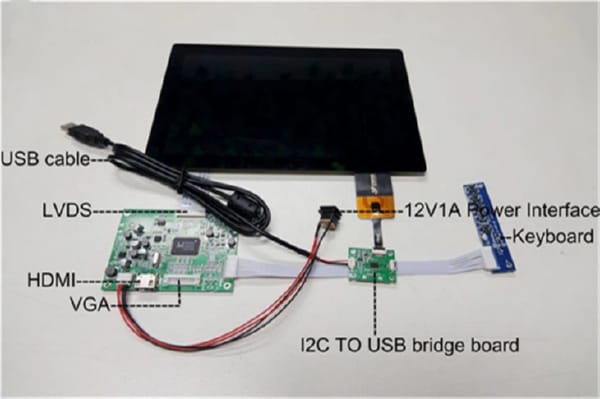

USB (Universal Serial Bus): Plug-and-Play Simplicity

USB is the global standard for connecting peripherals to PCs and other computing devices. Its primary advantage is standardization and ease of use.

How a USB Touch Panel Works as a HID Device

A USB touch panel typically identifies itself to the host system as a Human Interface Device (HID). This is the same class as a mouse or keyboard. As a standard HID device, it can use generic drivers built into most operating systems (like Windows, Linux, and Android).

Advantages: Standardization and Ease of Use with PCs/SBCs

The plug-and-play nature of USB eliminates the need for custom driver development in many cases. This dramatically accelerates the integration of a touch screen with a PC or a Single Board Computer (SBC) like a Raspberry Pi.

Considerations: Higher Power Consumption and Complexity

The USB protocol is more complex than I2C and typically has a higher power consumption. For battery-powered embedded devices, this can be a significant drawback. The physical connector is also larger than a simple pin header.

RS232 (Recommended Standard 232): The Industrial Workhorse

While considered a legacy protocol in consumer electronics, RS232 remains a highly relevant and reliable choice for industrial applications due to its robustness.

The Basics of Serial Communication

RS232 is a point-to-point serial communication standard. It transmits data bit by bit over a single line, with defined voltage levels that make it highly resistant to electrical noise.

Advantages: Long-Distance Reliability and Noise Immunity

The key strengths of RS232 are its ability to transmit data reliably over long distances (up to 15 meters or more) and its excellent noise immunity. This makes it the preferred touch screen interface for factory floors and other electrically noisy environments.

Why RS232 is Still Relevant for Industrial Panels

In an industrial panel application, the touch screen might be located far from the main control cabinet. RS232's long-distance capability and robustness ensure that touch data is transmitted without corruption, which is critical for operational safety and reliability.

I2C vs. USB vs. RS232: A Head-to-Head Comparison for Touch Panels

This table summarizes the key trade-offs to help you visualize the best fit for your project.

| Feature | I2C Touch Screen | USB Touch Panel | RS232 Touch Panel |

|---|---|---|---|

| Ideal Host | Microcontroller (MCU) | PC, Single Board Computer | Industrial PC, PLC |

| Data Rate | Slower (100Kbps - 3.4Mbps) | Faster (12Mbps - 480Mbps+) | Slower (up to 115.2Kbps) |

| Cable Length | Very Short (<1m) | Medium (up to 5m) | Long (15m+) |

| Pin Count | Low (2 signal pins) | Medium (4 pins) | Low (3 pins for basic TX/RX/GND) |

| Driver Dev | Typically required | Often uses standard HID drivers | Typically straightforward |

| Noise Immunity | Lower | Moderate | Excellent |

Selecting the Optimal Touch Screen Interface for Your Project

Use this checklist to guide your decision:

- What is your host device?If it's a microcontroller (MCU) on the same PCB, start with I2C.If it's a PC, Mac, or Raspberry Pi, USB is almost always the easiest choice.If it's an Industrial PC or PLC, consider RS232 for its robustness.

- What is the distance between the touch screen and the host?For distances over a meter, I2C is not suitable. USB or RS232 are better options.

- What is the operating environment?For electrically noisy environments like a factory floor, RS232 offers the best noise immunity.

- What are your development resources?If you want to avoid custom driver development, a USB Touch Panel configured as a HID device is the fastest path to a working prototype.

Frequently Asked Questions (FAQ)

1. Are there other interfaces like SPI available for touch screens? Yes, SPI (Serial Peripheral Interface) is another common interface for embedded system peripherals. It is generally faster than I2C but requires more pins. While some touch screen controller ICs support SPI, it is less common as a standard module-level interface compared to I2C, USB, and RS232.

2. Do I need to write my own driver for these interfaces? For a USB Touch Panel configured as a standard HID, you often do not need to write a custom driver for major operating systems. For an I2C touch screen or RS232 interface connected to an embedded system, you will typically need to write or port a driver to read and interpret the data from the controller.

3. How does the choice of interface affect power consumption? The interface can have a notable impact on power consumption. I2C is generally very low-power, making it ideal for battery-operated devices. USB has higher overhead and power requirements. RS232's power draw depends on the specific transceiver ICs used but is typically higher than I2C. Our datasheets provide detailed power specifications for each interface option. Contact our engineering team for a free technical consultation and datasheets.