Any manufacturer can produce a datasheet with impressive specifications. But how can you be certain a display will perform reliably over years of real-world use in a demanding environment? The true measure of durability is not found on paper, but proven through rigorous, objective testing. This article takes you on a virtual tour of Xingyue Technology's in-house reliability testing lab. We'll show you how we go beyond standard quality control to validate the long-term performance of every industrial touch screen and rugged display we build.

Why In-House Reliability Testing is a Non-Negotiable

For us, comprehensive in-house reliability testing is not an optional extra; it is a fundamental part of our commitment to quality and a core component of our engineering process.

Moving from "Claimed" to "Proven" Performance

Claims of "ruggedness" are easy to make. We believe in providing proof. By subjecting our products to standardized, repeatable tests that simulate harsh conditions, we transform claimed specifications into proven, quantifiable performance data.

Reducing Field Failures and Total Cost of Ownership

Identifying potential weaknesses in the lab, before a product ships, is the most effective way to prevent costly field failures. A display that is proven to be reliable reduces your maintenance costs, protects your brand's reputation, and lowers the overall total cost of ownership for your end customers.

Test Category 1: Climate & Environmental Testing

Our lab is equipped with a range of environmental chambers to simulate the extreme climatic conditions our products might face, from freezing temperatures to corrosive sea air. This environmental testing is critical for any outdoor or mobile application.

High/Low-Temperature Storage and Operation Tests

We place displays in chambers and cycle them between extreme cold and hot temperatures (e.g., -30°C to +85°C). We test their ability to not only survive these temperatures during storage but, more importantly, to operate flawlessly while at these extremes.

Thermal Shock Tests: Simulating Rapid Temperature Changes

A thermal shock test subjects a product to instantaneous, extreme temperature shifts. This brutal test assesses the integrity of material bonds and solder joints, ensuring that rapid temperature changes won't cause delamination or component failure.

Humidity and Salt Spray Tests for Corrosion Resistance

To validate performance in humid or coastal environments, we use humidity chambers and salt spray test chambers. These tests accelerate the corrosion process, allowing us to verify the long-term corrosion resistance of all exposed metals and coatings.

Test Category 2: Mechanical Stress & Durability Testing

A rugged display must be able to withstand the physical abuse of transportation, installation, and daily use. Our mechanical durability testing protocols are designed to ensure just that.

Vibration and Shock Tests for Transportation and Industrial Use

Our electrodynamic shakers subject products to a specified spectrum of random vibrations and mechanical shocks. This vibration test simulates the stresses of being mounted on a vehicle or industrial machine, ensuring that internal components and connections remain secure.

Drop Tests: Simulating Accidental Falls

We perform controlled drop tests from various heights and onto different surfaces. This helps us validate the impact resistance of the cover glass, bezel, and housing, ensuring the device can survive accidental falls.

Static Load and Pressure Tests

To test the structural integrity of the display assembly, we apply a controlled static load or pressure to the screen's surface. This verifies that the screen will not deform or fail under sustained pressure.

Test Category 3: Accelerated Aging and Lifetime Tests

How will a display perform after five years in the field? Our accelerated aging and lifetime test protocols provide the answer.

UV Accelerated Aging Tests for Outdoor Displays

Using specialized UV chambers that follow standards like ASTM G154, we expose our outdoor displays to intense ultraviolet radiation. This test simulates years of sun exposure in a matter of weeks, allowing us to verify the long-term stability of inks, adhesives, and polarizers against yellowing and degradation.

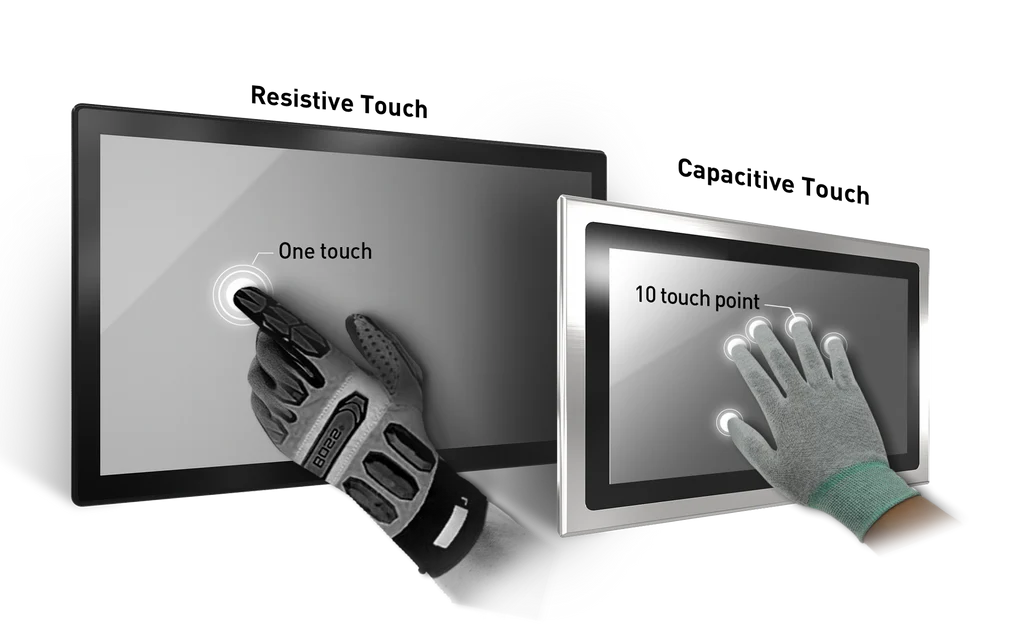

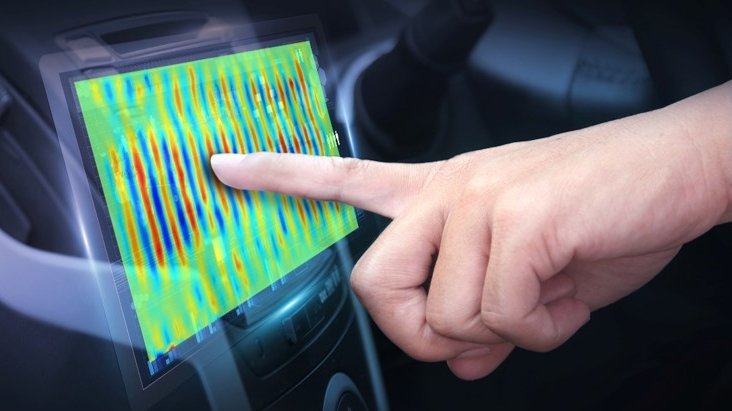

Touch and Button Press Lifetime Tests (e.g., 1 Million Clicks)

We use automated rigs to repeatedly press physical buttons or tap the touch screen millions of times. This mechanical endurance test verifies that the touch sensor and any integrated buttons will continue to function reliably throughout the product's intended lifespan.

From Our Lab to Your Application: A Commitment to Proven Reliability

Every test conducted in our lab has a single purpose: to provide you with the confidence that the display you integrate into your product is built to last. Our commitment to in-house reliability testing is a commitment to your project's success. It's how we ensure that every rugged display and industrial touch screen bearing the Xingyue name delivers on its promise of proven, long-term performance.

Frequently Asked Questions (FAQ)

What industry standards (like MIL-STD-810G) do your reliability tests follow

Our tests are designed based on a variety of internationally recognized standards, including IEC standards for environmental testing and specific sections of MIL-STD-810G for mechanical shock and vibration, where applicable. We work with clients to test against the specific standards required for their industry.

Can you perform custom reliability tests based on our specific project requirements?

Yes, absolutely. We frequently design custom reliability tests to validate a product against a client's unique use case or environmental challenges. This collaborative approach ensures the product is perfectly suited for its intended real-world application.

How does reliability testing affect the final cost and lead time of a product?

While comprehensive reliability testing adds to the initial development time and cost, it is a crucial investment that significantly reduces long-term expenses. By identifying and correcting potential design flaws early, it prevents costly warranty claims, field service calls, and damage to your brand's reputation. [Need a display that is proven to survive your application's environment? Share your project's reliability requirements with our engineers.](