In the world of manufacturing, an ISO 9001 certified logo is a vital mark of credibility. But what truly separates a good supplier from a great one? For projects where failure is not an option, true confidence comes from a deep, transparent, and rigorous quality control process. Many clients ask, "What is the difference between quality control and quality assurance?" While assurance sets the standards, control ensures every single product meets them. At Xingyue Technology, we believe our commitment to quality goes far beyond a certificate on the wall. It’s embedded in every component we touch and every process we perform. Discover a partnership built on a foundation of quality.

Why "ISO 9001 Certified" is Just the Starting Point for Reliability

Achieving ISO 9001 certification is a significant accomplishment. It demonstrates a commitment to a structured quality management system. However, we view it as the baseline, not the finish line. True reliability is forged in the daily execution of meticulous standards.

The True Meaning of Quality Assurance in Manufacturing

For us, quality assurance is our promise. It’s the comprehensive system of policies, procedures, and standards we design to ensure excellence. But this promise is only fulfilled through an active, vigilant quality control process. It’s the hands-on verification that turns our quality promise into your product reality.

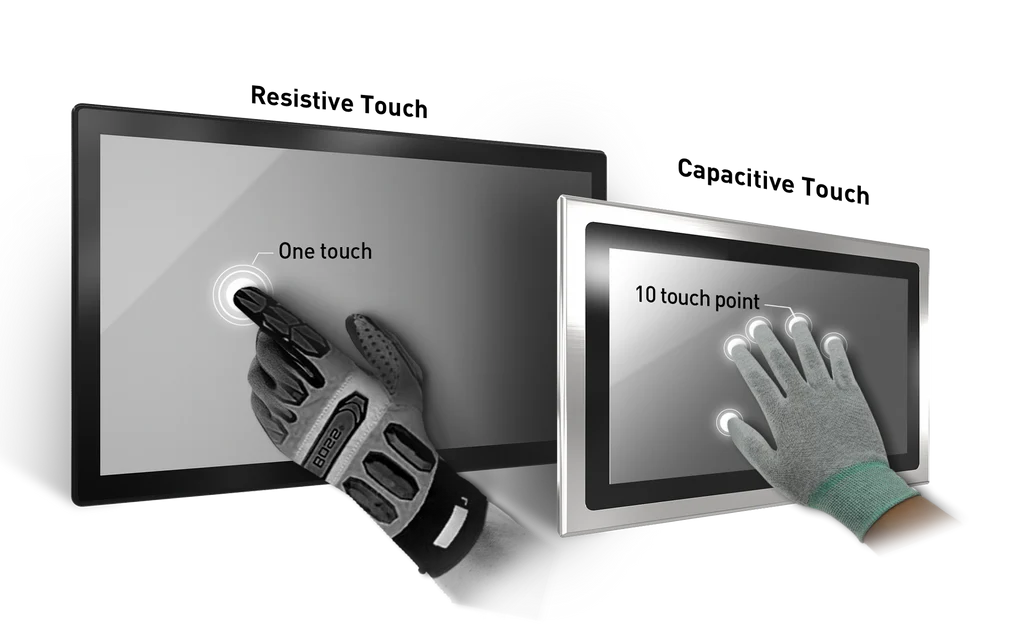

Setting a Higher Standard for Industrial Touch Screens

An Industrial Touch Screen faces harsh conditions—vibration, temperature swings, and constant use. A standard quality check isn't enough. That's why we've developed internal standards that often exceed typical industrial touch screen testing standards, ensuring our products thrive where others might fail.

Stage 1: The Gateway – Our IQC for Flawless Raw Materials

A superior final product begins with superior raw materials. Our Incoming Quality Control (IQC) process is the stringent gateway through which all components must pass. Nothing enters our production line without first meeting our exacting standards.

Vetting Core Components: Touch ICs and Glass Cover Inspection

Every component is critical. We conduct detailed inspections on core parts like touch controller ICs and glass covers. As an experienced Glass Cover Manufacturer ourselves, we know exactly what to look for in terms of optical clarity, surface perfection, and dimensional accuracy.

Supplier Audits and Partnership Quality Standards

Our quality control extends to our partners. We conduct regular supplier audits to ensure they share our commitment to excellence. We build long-term relationships with suppliers who can consistently meet our high material standards.

How We Guarantee Material Consistency from Batch to Batch

Consistency is key for large-scale production. Through strict batch-tracking and material testing, our IQC team ensures that the materials used in your first unit are identical in quality to those in your thousandth.

Stage 2: In-Process Vigilance – IPQC for Perfect Manufacturing

Once approved materials enter our smart assembly lines, our In-Process Quality Control (IPQC) team takes over. They act as vigilant guardians throughout the entire manufacturing process, ensuring every step is executed flawlessly.

Real-Time Monitoring on Our Smart Assembly Lines

Our IPQC engineers conduct continuous patrols and inspections. They monitor automated equipment, verify process parameters, and ensure that every action on the assembly line adheres to our established best practices.

First Article Inspection (FAI) Protocols

Before any mass production run begins, a "first article" is produced. This initial unit undergoes an exhaustive inspection to verify that all setups, materials, and processes are perfectly aligned with the project's specifications. FAI prevents mass defects before they can start.

Statistical Process Control (SPC) for Defect Prevention

We use data to drive quality. By employing Statistical Process Control (SPC), we monitor and control our manufacturing process. This allows us to predict and prevent potential quality deviations, shifting from defect detection to defect prevention.

Stage 3: The Final Checkpoint – OQC Before Your Product Ships

Before any product is packaged and shipped, it must pass our final and most comprehensive quality gate: Outgoing Quality Control (OQC). This is our final promise to you that the product you receive is perfect.

100% Functional and Cosmetic Touch Screen Testing

Every single touch screen undergoes a full functional test. We check for responsiveness, accuracy, multi-touch capability, and more. A meticulous cosmetic inspection also ensures there are no scratches, blemishes, or imperfections. This is the core of our touch screen testing protocol.

Verifying Performance Against Your Exact Specifications

Our OQC team works directly from your approved specifications. We verify every detail, from brightness and color gamut to interface connectivity. For a custom touch screen, this QC step is especially critical to ensure we've perfectly realized your vision.

Final Packaging and Handling Inspection

Quality control doesn't end with the product itself. We inspect the final packaging to ensure it provides adequate protection during transit. A product that arrives damaged is not a quality product.

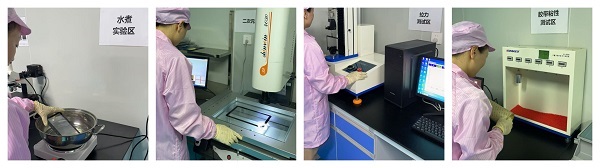

Going the Extra Mile: Inside Our In-House Reliability Testing Lab

This is where we go beyond the standard quality control process. Our in-house reliability testing lab is designed to simulate years of harsh use in a matter of days or weeks, giving you unparalleled confidence in the product's long-term durability.

Simulating a Lifetime of Use: Environmental and Climate Tests

Our products are subjected to extreme environmental testing. We place them in thermal shock chambers, cycling between high and low temperatures. We test them in high-humidity environments and expose them to salt spray to test for corrosion resistance.

Built for Tough Environments: Vibration, Drop, and Impact Testing

To ensure our screens can withstand physical stress, we conduct rigorous vibration tests, controlled drop tests, and IK-rated impact tests. This is how we validate the ruggedness of every Industrial Touch Screen we produce, ensuring they meet the toughest industrial touch screen testing standards.

Ensuring Flawless Performance: Signal Integrity and EMI Testing

In a world full of electronic devices, electromagnetic interference (EMI) is a real threat. Our lab performs EMI testing to ensure our screens perform reliably, even in electronically noisy environments like factory floors or hospitals.

Our Commitment to Quality: A Foundation for Your Success

Our multi-stage quality control process, from IQC to OQC and our extensive reliability testing, is more than just a procedure. It is our fundamental commitment to you. It's the foundation upon which we build not just touch screens, but trust. We believe that by delivering a product of uncompromising quality, we are directly contributing to the success and reputation of your own brand.

Frequently Asked Questions (FAQ)

1. What is the difference between quality control and quality assurance? Quality assurance is the proactive system of processes and standards designed to prevent defects. Quality control is the reactive process of inspecting and testing products to identify and correct defects. A robust strategy, like ours, integrates both to ensure comprehensive quality management.

2. How do you ensure quality for custom touch screen orders? For every custom touch screen project, a unique custom touch screen QC plan is created. This plan incorporates all your specific requirements into our IQC, IPQC, and OQC stages. Our FAI protocol is especially critical here to ensure the first unit perfectly matches your design before mass production.

3. What specific reliability tests do your industrial touch screens undergo? Our standard reliability testing for an Industrial Touch Screen includes high/low-temperature storage and operation tests, thermal shock tests, humidity tests, vibration tests, and often specific IK impact rating tests. We adhere to stringent industrial touch screen testing standards to guarantee performance in demanding environments.

4. How long does reliability testing take? The duration of reliability testing depends on the specific tests required and the standards we are validating against. A full suite of environmental and mechanical tests can range from a few days to several weeks. We work with you to define a testing plan that balances thoroughness with your project timeline. If you would like to learn more about the testing process, we invite you to contact us for detailed information and videos.