Executive Summary

Standard touch screens fail in outdoor kiosks due to intense sun glare, leading to poor user experience and lost revenue. The solution is specialized sunlight readable touch screens, which combine three core technologies: a high brightness display (1000+ nits), optical bonding to eliminate internal reflection, and anti-glare surface treatments. This approach not only ensures perfect screen clarity in any light but also significantly enhances the display's durability, guaranteeing a higher return on your investment.

Imagine a beautifully designed outdoor payment kiosk rendered completely useless on a sunny day. The screen, washed out by glare, is impossible to read. This scenario represents the single greatest challenge for outdoor interactive technology: visibility. Investing in standard displays for outdoor kiosks is a recipe for poor user experience and a failed project. The definitive solution is purpose-built sunlight readable touch screens. This guide will break down the science behind why standard screens fail and detail the core technologies that ensure flawless performance in any light.

The Core Problem: Why Standard Displays Fail in Direct Sunlight

A screen's ability to be read in bright light is not just about its own brightness; it's a battle between the light emitted by the display and the ambient light reflecting off its surfaces. In direct sunlight, standard displays lose this battle decisively.

Understanding Specular and Diffuse Reflection

Light reflects off a screen in two ways: specular (mirror-like) and diffuse (scattered). A standard screen's multiple layers (cover glass, air gap, LCD) create several surfaces for both types of reflection, which combine to create a "wall of light" that obscures the image.

When Ambient Light Overpowers Emitted Light

The core issue is the contrast ratio. In an outdoor environment, the intensity of reflected sunlight can be many times greater than the light emitted by a standard display. This drastically lowers the effective contrast, making the content on the screen appear faded or completely invisible.

The Impact on User Experience and ROI

An unreadable screen leads to user frustration, abandoned transactions, and a negative perception of your brand. For any commercial kiosk—from a transportation ticketing machine to a gas station payment terminal—this directly translates to a poor Return on Investment (ROI). The usability of the display is the foundation of the kiosk's success.

Solution Component #1: The High Brightness Display

The first step in winning the battle against ambient light is to increase the screen's own output. This is where a high brightness display comes in.

What Are Nits? Quantifying Screen Brightness

Screen brightness is measured in "nits" (candela per square meter, cd/m²). A typical indoor monitor or laptop screen has a brightness of 250-300 nits. This is sufficient for controlled indoor lighting.

Visualizing Brightness: 250 nits vs. 1000+ nits

| Brightness Level | Indoor Visibility (Office Lighting) | Outdoor Visibility (Direct Sunlight) | Ideal Application |

|---|---|---|---|

| 250-300 nits | Excellent | Unreadable. Washed out by glare. | Standard Indoor Monitors |

| 1000+ nits | Excellent (can be dimmed) | Clear and Legible. | High brightness display outdoor use |

Why 1000+ Nits is the Standard for Outdoors

For an outdoor touch screen to be effective, it needs to compete with the sun. The industry standard for a baseline sunlight readable display is a brightness of at least 1,000 nits. This level of output ensures the screen's emitted light is strong enough to maintain a good contrast ratio in bright, indirect sunlight.

Managing Power Consumption and Heat Dissipation

A high brightness display will naturally have higher power consumption. A critical part of a well-engineered solution is managing this through efficient LED backlights and effective thermal design to dissipate the extra heat, ensuring long-term reliability for your sunlight readable touch screen kiosks.

Solution Component #2: The Power of Optical Bonding

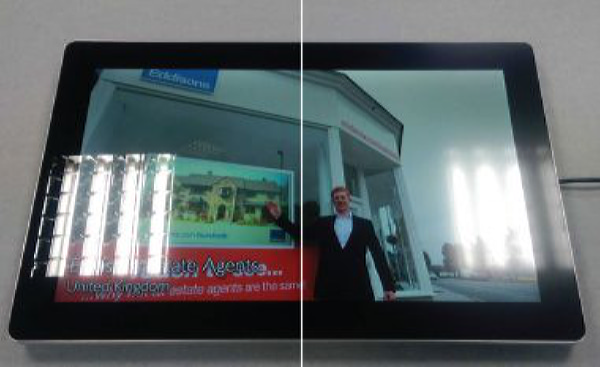

While high brightness is important, it's not the most critical factor. The most effective technology for enhancing outdoor visibility is optical bonding.

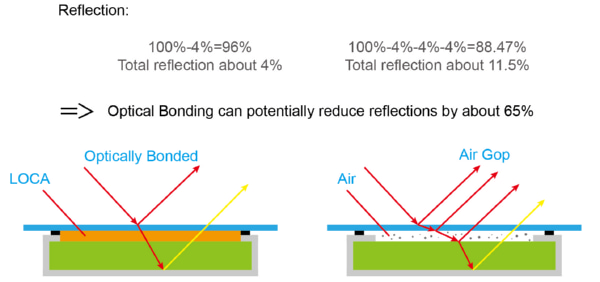

Eliminating the Air Gap to Reduce Internal Reflection

As discussed, the air gap in standard screens is a major source of performance-degrading reflections. Optical bonding is the process of filling this gap with an optical-grade resin, creating a single, solid optical unit. This eliminates the internal reflective surfaces entirely.

How Optical Bonding Dramatically Improves Contrast Ratio

By removing internal reflections, optical bonding ensures that more of the display's original light reaches the user's eyes. It also prevents ambient light from reflecting back and washing out the image. The result is a dramatic improvement in the contrast ratio.

Achieving Clarity Without Excessive Brightness

A key advantage of an optical bonding kiosk display is that it enhances visibility so effectively that you may not need an ultra-high brightness panel. An optically bonded 1,000-nit screen will often appear clearer and more readable than a non-bonded 1,500-nit screen, while consuming less power.

Solution Component #3: Anti-Glare and Anti-Reflective (AG/AR) Surface Treatments

The final piece of the puzzle is managing reflections on the very top surface of the screen.

Anti-Glare (AG): Diffusing Harsh Reflections

An anti-glare treatment involves microscopically etching the glass surface. This finish scatters incoming light, breaking up mirror-like reflections into a softer, less distracting haze. It is highly effective at reducing specular reflection.

Anti-Reflective (AR): Minimizing Surface Reflection

An anti-reflective coating is a multi-layer film applied to the glass that is engineered to reduce the amount of light that reflects off the surface. It is highly effective at increasing light transmission for the sharpest possible image.

Choosing the Right Treatment for Your Kiosk Location

The choice between AG and AR depends on the specific environment. An anti-glare outdoor kiosk screen is often preferred for direct sunlight applications, while AR is excellent for maintaining the highest image fidelity in bright but less direct light, such as in a bank ATM vestibule.

Beyond Visibility: Durability Benefits for Outdoor Touch Screens

The technologies used to create sunlight readable touch screens also make them inherently more durable.

Enhanced Impact Resistance

The resin used in optical bonding adds a shock-absorbing layer to the display stack-up, significantly increasing its resistance to impact and vibration.

Preventing Fogging and Moisture Ingress

By eliminating the air gap, optical bonding prevents moisture and dust from entering the display. This makes the screen immune to internal fogging in humid or changing temperatures.

Creating a Truly Rugged Outdoor Touch Screen

When you combine a high brightness display with optical bonding and a durable cover glass, you create more than just a visible screen; you create a truly rugged outdoor touch screen built to withstand the elements and public use, perfect for transportation ticketing machines and other demanding environments.

Investing in Usability: Why Sunlight Readable Technology is a Must-Have for Kiosks

Choosing a sunlight readable touch screen for your outdoor kiosks is not an upgrade; it is a fundamental requirement. It is an investment in the usability, reliability, and ultimately, the profitability of your project. By combining high brightness, optical bonding, and appropriate surface treatments, you ensure a positive user experience and maximize the ROI of your deployment.

Frequently Asked Questions (FAQ)

How many nits are considered "sunlight readable"? A brightness of 1,000 nits is generally considered the minimum threshold for a display to be considered "sunlight readable." For applications in very bright, direct sunlight, levels of 1,500 nits or higher may be required for optimal performance.

Does a high brightness display consume significantly more power? Yes, a high brightness display does have higher power consumption than a standard display. However, this can be mitigated. Using optical bonding enhances clarity so effectively that you can often achieve excellent readability without pushing the backlight to its absolute maximum, thus saving energy.

Can optical bonding be applied to any type of touch screen? Yes, optical bonding can be applied to both capacitive and resistive touch screens. The process is highly effective for any display assembly where reducing reflection and increasing durability are key objectives.

Don't let glare compromise your project's success. Whether you are designing a new line of outdoor kiosks or upgrading an existing one, our engineering team can help you select the perfect sunlight readable display.

Request a Free Consultation with Our Experts Now!